What is a circular system?

In the past, the production of new products was based on a linear system. Resources were transformed into products that were used and then disposed of.

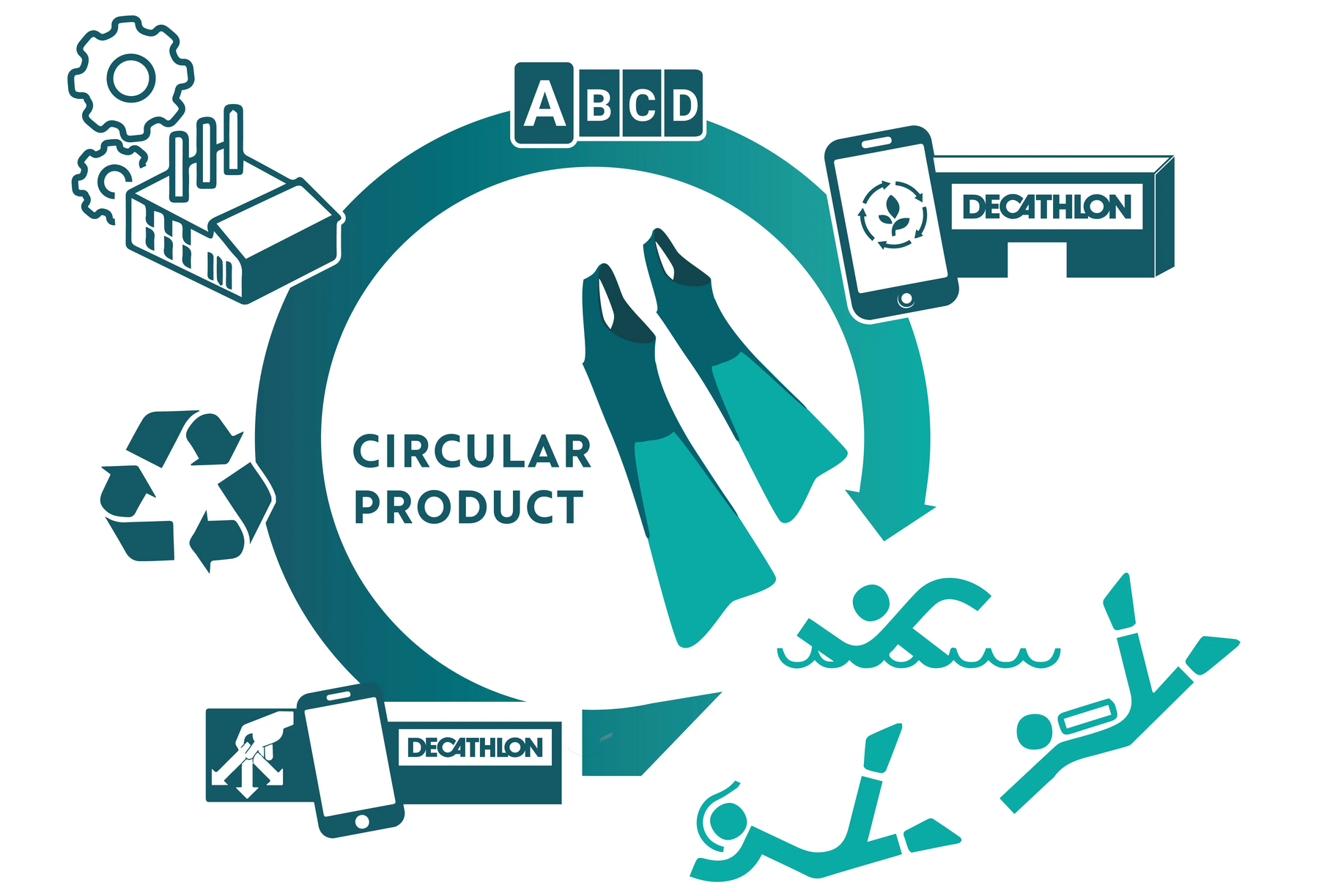

The circular system aims to change all this by limiting the waste of resources and environmental impacts. This can be achieved by transforming the product's life cycle from a straight line into a loop. The aim? At the end of its life cycle, the product becomes a resource for the production of other products, instead of going to waste.